Production & technologies at B+B

Development and production of thermocouple connectors, temperature, humidity and pressure sensors

Our own development and construction area, as well as our own production, allows us to react flexibly to customer-specific wishes. Many of our employees have many years of experience in measurement technology. They are at your disposal with their knowledge and skills, so that your desired production can be implemented promptly.

We are a modern company and meet the highest standards of quality and precision. Our employees are constantly trained so that they are always up to date and can advise you optimally.

We constantly check the quality of our products in order to meet the high quality demands of our customers. Our modern production facilities are pleasant to work in – an important factor for the quality of work. We want effective communication and we are open to objective criticism. We encourage the ideas and own initiatives of our employees in the best possible way.

The B+B Thermo-Technik produces high quality products since 1984

Quality and customer proximity are fixed components of the company strategy, which is why B+B temperature sensors and thermocouple connectors, humidity sensors and pressure sensors are mainly manufactured in Germany and in 100% subsidiaries worldwide.

This ensures constant quality controls, flexible reactions to customer requests and changes as well as prompt production and deliveries.

Our CNC department

Technologies in metrology include state-of-the-art CNC technology for the production of turned or milled parts. Through the additional use of CAM, geometry data for raw and finished parts can be read directly from the CAD program. This ensures an even more economical use of the CNC machinery.

The use of these technologies enables us to process:

- high-alloy acid-resistant steels

- non-ferrous metals

- plastics

In-house development & construction

Our in-house development and design department enables us to respond quickly and individually to customer requests. It does not matter whether it is a complete individualization or a desired adaptation of one of our standard articles. Our team is at your side with its technical know-how and experience to realize high-quality products.

- Short decision-making processes & rapid coordination procedures

- Fast processes

- Internal networking of our departments

- High quality through know-how and experience

Calibration laboratory at B+B

With our in-house calibration laboratory, we can address the issue of the constantly growing quality demands placed on our customers and the associated industries and sectors. Stricter guidelines are leading to increasingly stringent requirements and specifications for production, manufacturing and storage processes.

With the service of our calibration laboratory accredited by the German Accreditation Body (DAkkS) in accordance with DIN EN ISO/IEC 17025:2018 with regard to the thermodynamic measured variables of temperature and relative humidity, we can help you with this.

We can offer you the following calibrations as a service:

- ISO factory calibration

- DAkkS calibration

PCB assembly

Our PCB assembly basically means the assembly of printed circuit boards using the latest technologies. This aspect is therefore an important step in the production of electronic assemblies, which we can carry out directly on site. Our many years of experience and expertise allow us to implement two different types of assembly: single-sided and double-sided PCB assembly.

- Cost-effective implementation

- Possible reduction in the overall size of the end product

- Fast and experienced response options

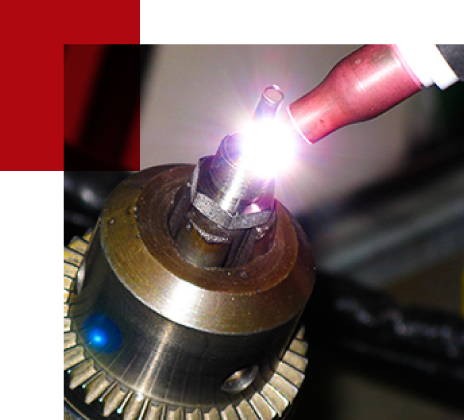

Laser/plasma/WIG shielded arc welding technology

Thanks to our modern facilities and equipment, B+B can also implement various welding processes. In laser welding, the energy is supplied via a laser and is therefore primarily used for welding components that need to be welded at high speed, with a slim weld seam shape and low thermal distortion.

Gas-shielded welding also includes a group of welding processes that are summarized under the term arc welding, which in turn belongs to the group of fusion welding.

In plasma welding, a plasma serves as the corresponding heat source. The plasma is an electrically conductive gas that is highly heated by an electric arc.

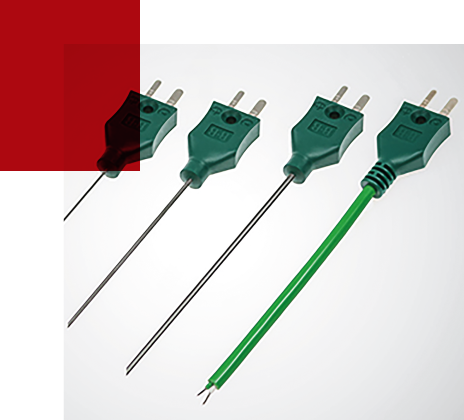

Production of sheath thermocouples & sheath resistance thermometers

Sheathed thermocouples are special thermocouples that are protected by compact insulation and a metal sheath. Due to their robustness and easy handling, they are used in industry, among other things. In addition, they are extremely flexible and are characterized by extremely high vibration resistance.

Sheath resistance thermometers are sensors that use the temperature-dependent change in resistance of platinum resistors. They are generally supplied in flexible and mineralized versions.

Injection molding technology

B+B Thermo-Technik GmbH is particularly characterized by flexible reaction branches. It is precisely for this reason that this flexibility also applies to the field of injection molding. This is basically a primary molding process, which is mainly used in plastics processing. An injection molding machine liquefies the respective material, places it in the desired shape and injects it under pressure.

- For processing a wide range of plastics

- Suitable for e.g. PEEK, PP

Laser labeling

Another flexible aspect at B+B is our in-house laser marking. We can provide various materials (e.g. metals and plastics) with individual marking. This laser marking is used for internal identifiers, among other things, and is also used for customer-specific marking.

- Laser marking for metals

- Marking also for plastics

Newsletter registration

Stay up to date with us free of charge. Don't miss any more news, novelties or information with our free newsletter!